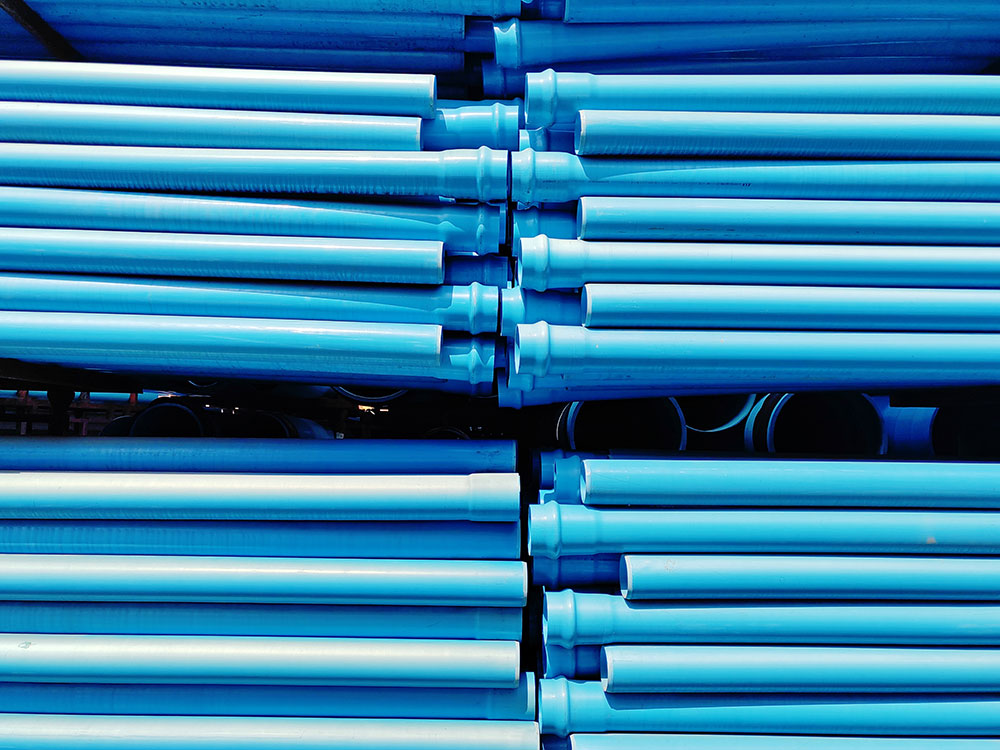

PVCO Pipe Fittings

Developed from PVCO pipes through a special tensile orientation process, PVCO fittings offer exceptional performance, long service life, and lightweight properties. As part of a complete PVCO pipe system, these oriented PVC fittings are designed to replace traditional PVC-U injection molded and steel-plastic pipe fittings across various applications.

Manufactured to meet oriented PVC pipe standards such as ISO PVCO pipes and ISO PVCO fittings, our products are available in multiple PVCO pipe pressure ratings and PVCO pipe diameters, including PVCO pipe Grade 450 and PVCO pipe Grade 500. Key PVCO pipe advantages include being lightweight, corrosion-resistant, impact-resistant, and UV-stable.

Explore our full range of PVCO pipe accessories and PVCO fittings sets for efficient PVCO pipe installation. For PVCO pipe specifications, PVCO pipe price details, or inquiries about custom PVCO pipes and fittings, contact us—a trusted PVCO pipe manufacturer and PVCO pipe supplier.

Inquiry Now- Description

- Applications

- Specification

- Faqs

High Strength & Pressure Resistance of PVCO Pipe Fittings

Utilizing biaxial orientation technology, PVCO Pipe Fittings deliver superior impact resistance and ring stiffness compared to conventional PVC.

This ensures excellent performance under high water pressure and demanding conditions.

Extended Lifespan

These fittings are corrosion-resistant and scale-proof, with a service life of over 50 years—far longer than traditional metal fittings.

Their durability reduces replacement frequency and overall maintenance costs.

Safe & Eco-Friendly PVCO Pipe Fittings

PVCO Pipe Fittings comply with international water safety standards and are free from heavy metal leaching,

ensuring clean and safe water for municipal, agricultural, and industrial systems.

Lightweight & Easy to Install

Weighing only one-fifth of metal fittings, they are easy to transport and handle.

Installation is flexible with options such as solvent cementing, flange connections, and rubber gasket seals, improving efficiency on site.

Low Flow Resistance & Energy Saving

The smooth inner wall of PVCO Pipe Fittings minimizes head loss, reducing pumping energy consumption

while ensuring efficient and cost-effective water transmission.

Customization

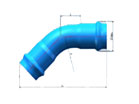

We provide various specifications,including PVCO pipe coupler,PVCO sliding coupler,PVCO pipe 11.25 degree elbow bend,PVCO pipe 22.5 degree elbow bend,PVCO pipe 45 degree elbow bend and PVCO pipe 90 degree elbow bend.

- Anyue County Comprehensive Water Supply Project (DN110-DN630)

- Renshou County Reclaimed Water Plant Project (DN315-DN450)

- Leibo County Drinking Water Project, Liangshan Prefecture (DN200)

- 2019 Rural Drinking Water Security Consolidation and Upgrading Project, Wanzhou District, Chongqing Municipality (DN110)

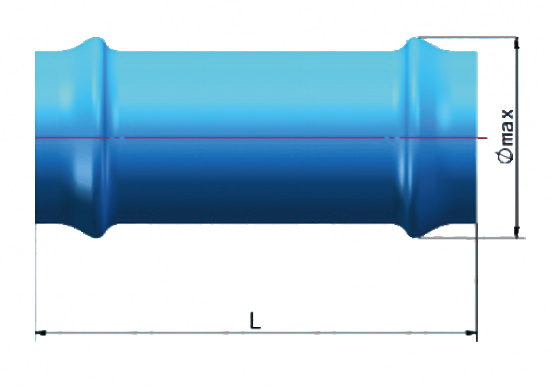

Coupler

| DN | PN | max(mm) | L(mm) | Z(mm) | Weight(kg) | Reference |

|---|---|---|---|---|---|---|

| 110 | 10/16 | 140 | 330 | 67 | 0.70 | TY110PN16C |

| 160 | 10/16 | 197 | 404 | 90 | 1.74 | TY160PN16C |

| 200 | 10/16 | 242 | 448 | 97 | 3.19 | TY200PN16C |

| 250 | 10/16 | 300 | 519 | 124 | 6.00 | TY250PN16C |

| 315* | 10/16 | 376 | 610 | 155 | 11.52 | TY315PN16C |

| 355* | 10/16 | 418 | 660 | 172 | 13.19 | TY355PN16C |

| 400* | 10/16 | 475 | 705 | 187 | 21.95 | TY400PN16C |

Sliding Coupler

| DN | PN | max(mm) | L(mm) | Z(mm) | Weight(kg) | Reference |

|---|---|---|---|---|---|---|

| 110* | 10/16 | 140 | 330 | 0 | 0.70 | TY110PN16SC |

| 160* | 10/16 | 197 | 404 | 0 | 1.74 | TY160PN16SC |

| 200* | 10/16 | 242 | 448 | 0 | 3.19 | TY200PN16SC |

| 250* | 10/16 | 300 | 519 | 0 | 6.00 | TY250PN16SC |

| 315* | 10/16 | 376 | 610 | 0 | 11.52 | TY315PN16SC |

| 355* | 10/16 | 418 | 660 | 0 | 13.19 | TY355PN16SC |

| 400* | 10/16 | 475 | 705 | 0 | 21.95 | TY400PN16SC |

11.25° Socketed Bend

| DN | PN | max(mm) | L(mm) | Z(mm) | Radius(mm) | Weight(kg) | Reference |

|---|---|---|---|---|---|---|---|

| 110* | 10/16 | 140 | 370 | 50 | 165 | 0.78 | TY110PN16B11 |

| 160* | 10/16 | 197 | 454 | 69 | 240 | 1.90 | TY160PN16B11 |

| 200* | 10/16 | 242 | 513 | 78 | 300 | 3.54 | TY200PN16B11 |

| 250* | 10/16 | 300 | 604 | 99 | 375 | 6.74 | TY250PN16B11 |

| 315* | 10/16 | 376 | 720 | 124 | 475 | 13.09 | TY315PN16B11 |

| 355* | 10/16 | 418 | 788 | 140 | 550 | 15.15 | TY355PN16B11 |

| 400* | 10/16 | 475 | 848 | 153 | 600 | 25.31 | TY400PN16B11 |

22.5° Socketed Bend

| DN | PN | max(mm) | L(mm) | Z(mm) | Radius(mm) | Weight(kg) | Reference |

|---|---|---|---|---|---|---|---|

| 110 | 10/16 | 140 | 403 | 66 | 165 | 0.84 | TY110PN16B22 |

| 160 | 10/16 | 197 | 504 | 93 | 240 | 2.11 | TY160PN16B22 |

| 200 | 10/16 | 242 | 577 | 108 | 300 | 3.96 | TY200PN16B22 |

| 250 | 10/16 | 300 | 685 | 136 | 375 | 7.59 | TY250PN16B22 |

| 315* | 10/16 | 376 | 824 | 172 | 475 | 14.85 | TY315PN16B22 |

| 355* | 10/16 | 418 | 909 | 196 | 550 | 17.30 | TY355PN16B22 |

| 400* | 10/16 | 475 | 982 | 213 | 600 | 28.97 | TY400PN16B22 |

45° Socketed Bend

| DN | PN | max(mm) | L(mm) | Z(mm) | Radius(mm) | Weight(kg) | Reference |

|---|---|---|---|---|---|---|---|

| 110 | 10/16 | 140 | 440 | 102 | 165 | 0.98 | TY110PN16B45 |

| 160 | 10/16 | 197 | 567 | 144 | 240 | 2.52 | TY160PN16B45 |

| 200 | 10/16 | 242 | 663 | 173 | 300 | 4.80 | TY200PN16B45 |

| 250 | 10/16 | 300 | 796 | 217 | 375 | 9.29 | TY250PN16B45 |

| 315* | 10/16 | 376 | 969 | 274 | 475 | 18.37 | TY315PN16B45 |

| 355* | 10/16 | 418 | 1079 | 314 | 550 | 21.61 | TY355PN16B45 |

| 400* | 10/16 | 475 | 1172 | 342 | 600 | 36.31 | TY400PN16B45 |

90° Socketed Bend

| DN | PN | max(mm) | L(mm) | Z(mm) | Radius(mm) | Weight(kg) | Reference |

|---|---|---|---|---|---|---|---|

| 110 | 10/16 | 140 | 400 | 199 | 165 | 1.26 | TY110PN16B90 |

| 160* | 10/16 | 197 | 535 | 285 | 240 | 3.33 | TY160PN16B90 |

| 200* | 10/16 | 242 | 640 | 348 | 300 | 6.48 | TY200PN16B90 |

| 250* | 10/16 | 300 | 779 | 437 | 375 | 12.70 | TY250PN16B90 |

| 315* | 10/16 | 376 | 963 | 552 | 475 | 25.41 | TY315PN16B90 |

| 355* | 10/16 | 418 | 1084 | 636 | 550 | 30.25 | TY355PN16B90 |

| 400* | 10/16 | 475 | 1185 | 694 | 600 | 50.98 | TY400PN16B90 |

socketed reducer

| DN/DN | PN | φmax | L(mm) | Z(mm) | Weight(kg) | Reference |

|---|---|---|---|---|---|---|

| 110 / 90 | 10/16 | 140 | 350 | 60 | 0.7 | TY110R90PN16 |

| 125 / 110 | 10/16 | 160 | 440 | 90 | 1.1 | TY125R110PN16 |

| 140 / 110 | 10/16 | 180 | 445 | 105 | 1.49 | TY140R110PN16 |

| 160 / 110 | 10/16 | 205 | 460 | 110 | 1.87 | TY160R110PN16 |

| 160 / 140 | 10/16 | 210 | 470 | 70 | 1.97 | TY160R140PN16 |

| 200 / 160 | 10/16 | 250 | 500 | 110 | 3.2 | TY200R160PN16 |

| 225 / 160 | 10/16 | 275 | 555 | 200 | 4.88 | TY225R160PN16 |

| 225 / 200 | 10/16 | 285 | 570 | 90 | 4.25 | TY225R200PN16 |

| 250 / 200 | 10/16 | 300 | 580 | 125 | 5.65 | TY250R200PN16 |

| 315 / 250 | 10/16 | 365 | 660 | 155 | 10.50 | TY315R250PN16 |

| 400 / 315 | 10/16 | 470 | 780 | 165 | 18.89 | TY400R315PN16 |

*New molds need to be developed, with a minimum order quantity (MOQ) of 1,000 pieces and a lead time of 4 months.

Other specifications between DN110 and DN400 can be customized, such as DN125, DN140, etc.

1. Why is my PVCO fittings leaking after installation?

Leaks may occur due to improper installation, misalignment, or insufficient solvent cement. Check the joint and reinstall if necessary. For persistent issues, contact our support team.

2. Can i request custom sizes or specifications?

Yes, we offer custom manufacturing for bulk orders. Contact our sales team with your requirements.